The spread of use of hydraulic quick couplings is constantly growing thanks to the benefits that these items ensure on a lot of different applications in terms of connection speed, reliability and ease of use. Considering the vast range of products available on the market and bearing in mind that each single quick coupling is actually made up of two parts (the female half, or socket, and the male half, or plug) it’s easy to realize how important it is to be capable of identifying with certainty the quick release coupling half to order. For instance, everyone who needs to purchase a hydraulic implement to connect it to a power source has generally to indicate which size and kind of quick release couplings must be installed on the implement, in order to rely on mutually compatible coupling halves when hooking up implement hydraulics to the power source; another situation where it’s necessary to identify a quick release coupling occurs when service parts (either seals or the whole coupling) are needed for ordinary or extraordinary maintenance.

This article will deal with the main aspects related to the identification of quick couplings and list tips and tools that facilitate the identification.

Types of Hydraulic Quick Couplers

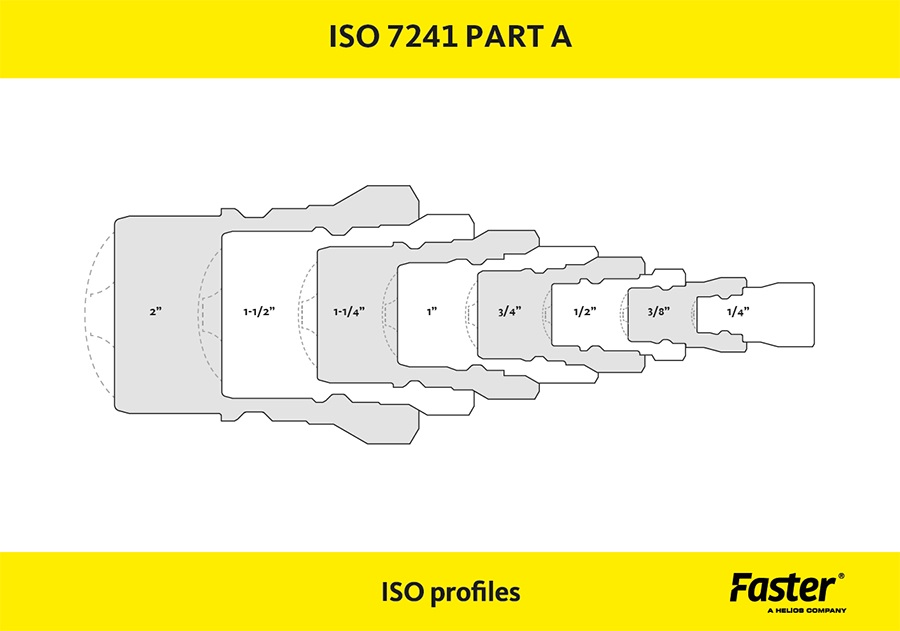

As already mentioned, there’s a myriad of different quick couplings available on the market but the sleeve retraction type (with ball or poppet valve) compliant with ISO 7241 standard (series A and B) and the flat face type are for sure the most common ones. Find out in this article which are the different types of hydraulic quick couplers.

Factors to Consider When Identifying Hydraulic Quick Couplers

The main elements which can help to identify a quick release coupling are the stampings that may be present on the surface of the coupling (name or logo of the manufacturer and part number) as well as its profile and dimensions.

How to Identify Hydraulic Quick Couplers

Readable stampings allow the identification of manufacturer's name and product series. The following step is to verify, by means of catalogs generally available on manufacturers websites, whether the series in question complies with an international standard or if it’s a proprietary profile; in the latter case it will be necessary to order a product of the same brand and series or, alternatively, a product of a different brand whose profile is however guaranteed as interchangeable with the series in question. Furthermore, if the quick coupling size cannot be clearly understood through the stampings (dash size is often indicated, but that’s not a universal rule) it can be determined by comparing dimensions and diameters measured on the quick coupling with dimensional data shown in the catalogue.

When it’s not possible to identify a quick coupling through the stampings, the use of charts such as the one available on the Faster website can be of great help in recognizing profile and size of a quick coupling complying with ISO 7241 (A and B) or with ISO 16028 just by laying the physical part down on the chart and verifying if it matches with a specific profile and size.

When dealing with other types of quick release couplings, if one is totally sure that two parts match with regard to the profile, he can measure main dimensions and compare them with catalog data to identify the part number to order.

If one’s looking for a spare part, he must also pay attention to the type of rear thread on the quick coupling he wants to replace; readable stampings are in general the only available meant to identify this product feature.

Common Mistakes in Identifying Hydraulic Quick Couplers

In conclusion, it’s often possible and quite easy to identify the quick couplings to order, but we recommend to always carry out carefully the necessary checks.

Never forget finally that mixing brands is ok when dealing with ISO-interchangeable products, but mixing sizes by mistake leads in any case to a waste of time and money!